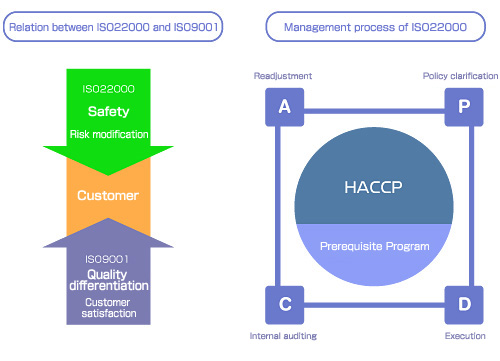

The ISO 22000 international standard specifies the requirements for a food safety management system that involves interactive communication, system management, prerequisite programs and HACCP principles.

Hazard Analysis and Critical Control Points (HACCP) is a systematic preventive approach to food safety and pharmaceutical safety that addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection.

As food processing maker, we accept current food safety issues with sincerity.

Our Quality Assurance Division is taking tours of factories to make management and guidance from quality and sanitary control

standpoint. We observe relevant legal provision and strive to enhance communication with customers and relevant organizations in order

to collect the latest information.

To deliver secure and safe products, we perform a variety of tests centers around bacteriological examination. We only use materials

which meet our standards and make shipment products pass the product test.

|

|

|

|

|

※Click images to enlarge.